Detergent Testing

The detergent industry is highly competitive with re-formulation an ongoing, continuous activity driven by the demand for exemplary performance, coupled with the need to reduce the environmental impact of routine cleaning. Enhanced performance at lower wash temperatures and the use of more environmentally friendly ingredients are key trends. Preserving the integrity, finish and quality of delicate fabrics and items is also essential.

To support formulation, for QC and for sensitive comparative performance testing, detergent manufacturers require relevant, reproducible, cost-efficient tests that can easily be applied in the laboratory. Ultimately, the performance and impact of detergents are assessed under real-life conditions using a domestic appliance, but this can be time-consuming, costly and has several other limitations, with respect to routine use within a laboratory.

Test Equipment

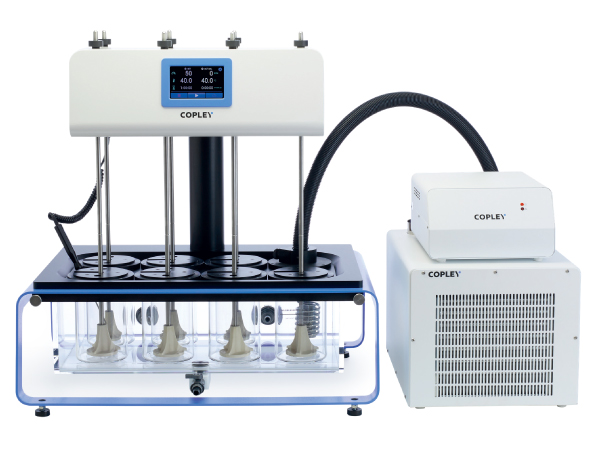

The tergotometer is a simple, but representative solution that directly addresses these limitations. Consisting of a number of miniature washing stations in a single benchtop instrument, the tergotometer delivers reproducible testing under closely controlled conditions, at much higher analytical throughput than can be achieved with a standard domestic appliance.

Test Conditions & Materials

Laundry samples with closely defined stains, pre-applied to a suitable substrate are commercially available in a range of fabrics, sizes and volumes, for many different stain types. Using such samples to standardise test conditions with respect to soil can significantly improve the repeatability of testing. Stain samples for dishwasher detergents testing are equally accessible, typically ‘baked-on’ to melamine tiles (mimicking the effect of porcelain), as well as glass and stainless steel. Beyond the issue of soil, there are several test conditions that can impact the test results including:

- Detergent concentration

- Temperature

- Water hardness, pH, bleach etc

- Washing and rinsing times

- Washing action

- The load

Analytical Assessment

Quantitative Analysis

Instruments for direct quantitative analysis include the colorimeter, whose relatively simple and robust construction make it ideal for QC applications. A spectrophotometer is more suited to high precision QC and research and development applications.

A product or surfactant can be considered successful when both criteria – stain removal and whiteness – have been met. Similar methods can be applied to the testing of light duty detergents, as used in domestic dishwashers, using a suitable accessory.

Manual Analysis

Once processed, laundry samples can be analysed manually (by eye) by comparison with a greyscale. Whiteness or yellowness indices can also be employed.