Friability Testing

Friability is the tendency for a tablet to chip, crumble or break following compression and can occur due to shock or abrasion during subsequent manufacturing steps, packaging or shipping. Normally limited to uncoated tablets and surfaces, it is a tendency that can significantly erode tablet quality. Tablets need to be hard enough so that they do not break up in the bottle, to safeguard product stability and dose uniformity, but sufficiently friable to disintegrate in the gastrointestinal tract and release the active(s).

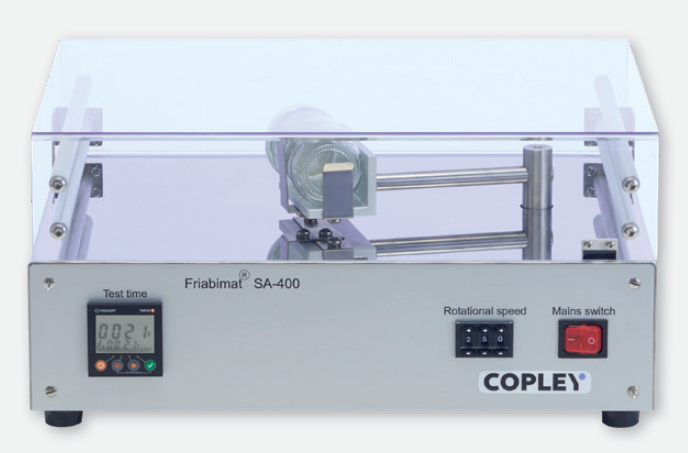

Chapters Ph. Eur. 2.9.7 and USP <1216> describe reproducible and standardised methods and equipment to determine the friability of a tablet.

A standard friability drum has an inside diameter of 287 mm and a depth of 38 mm. Each drum is fitted with a curved baffle which subject tablets to a drop of 156 mm during rotation. The sample (normally 10 tablets) to be tested is first weighed and then placed into the drum. The drum is then rotated 100 times at a speed of 25 rpm. Any loose dust from the sample is removed and the sample re-weighed. Friability of a sample is defined in terms of percentage (%) weight loss. A maximum weight loss of no more than 1% is considered acceptable for most tablets.

Attrition caused by tablets rubbing together can also be measured using this method with a special abrasion drum. For coated tablets, granules and spheroids, friability cannot be determined using a conventional friability tester, as the dosage form is too hard for meaningful weight loss measurements. Alternative equipment that oscillates the sample at high frequencies is available for this purpose (see Ph. Eur. 2.9.41). The abrasive forces generated by the horizontal shaking movement of the oscillating arm of this equipment allows users to easily optimise test conditions for each type of formulation with simple-to-use programmable controls.