Hardness Testing

Hardness (or breaking force) is a key physical characteristic of tablets, alongside friability. High hardness can delay disintegration and dissolution, while low hardness increases friability, leading to poor stability and dose uniformity. Optimizing hardness involves correlating it with disintegration, dissolution, and friability. Standard methods for assessing hardness are described in Ph. Eur. 2.9.8 and USP <1217>, which use a force gauge and motorized jaw to measure the force required to break a tablet, reported in Kiloponds or Newtons.

Together with friability, hardness (or breaking force) is a defining physical characteristic for a tablet. High hardness values may indicate for example, longer disintegration and dissolution times, compromising the speed of drug delivery. On the other hand, if hardness is too low, then friability may be also high, giving rise to poor product stability and compromised dose uniformity. By examining correlations between hardness, disintegration, dissolution and friability, a dosage form with optimum characteristics can be produced.

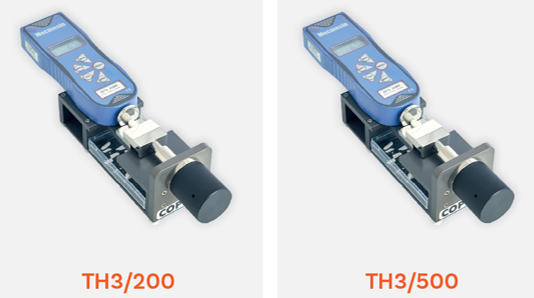

Chapters Ph. Eur. 2.9.8 Resistance to Crushing of Tablets and USP Chapter <1217>Tablet Breaking Force describe standardised methods for the assessment of tablet hardness.

A tablet is placed between two platens (jaws), one of which is attached to a force gauge with load cell and the other to a motor which provides the mechanical drive. The motorised jaw drives forward pressing the tablet against the fixed jaw until the tablet breaks. The motorised jaw then retracts and the load force required to break the tablet is recorded. The units of force normally employed to quantify breaking force are Kiloponds (Kilogram-Force) or Newtons.